As an entrepreneur, maintaining your tools and machinery is just as important as the craft itself. Your thickness planer, a crucial piece of equipment, is no exception. Over time, the gears in your thickness planer can accumulate grease, which can impact its performance and longevity. This article will direct you on how to clean grease from your thickness planer gears effectively.

Importance Of Cleaning Grease From Planer Gears

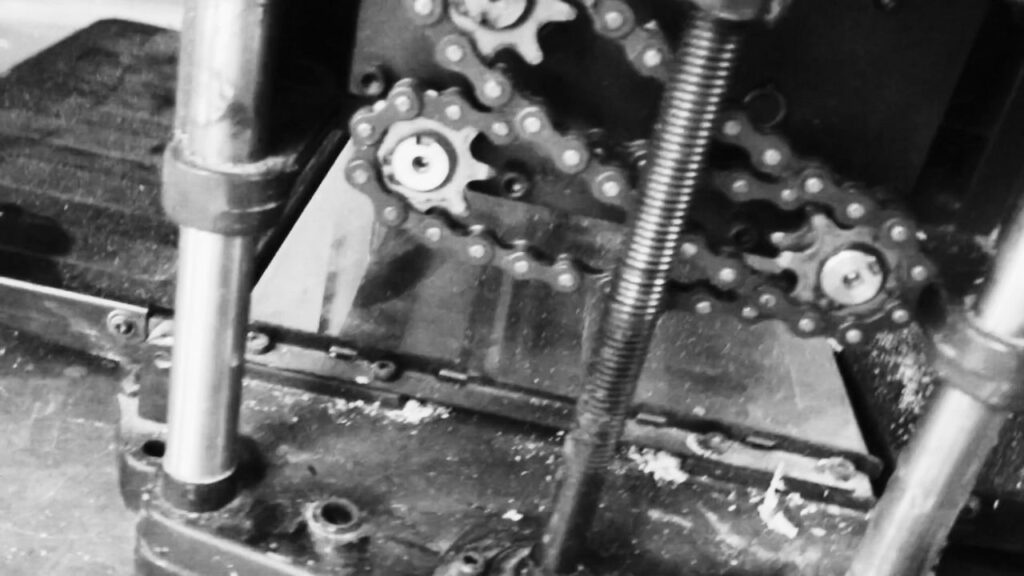

Maintaining a clean thickness planer isn’t just about keeping your workspace tidy, it’s about ensuring the efficiency and longevity of your tools. The accumulation of grease on your planer’s gears can aggravate wear and tear, slowing down the machine’s performance over time.

Additionally, grease can attract sawdust and debris, which can further complicate the machine’s function. Regularly cleaning the grease off your thickness planer gears is a vital maintenance task that will keep your machine running smoothly and extend its lifespan.

Tools & Materials Needed For Cleaning

Before we begin, it’s essential to gather the necessary tools and materials. To clean the grease from your thickness planer gears, you’ll need mineral spirits, a toothbrush, a clean rag, and a vacuum or spray gun. Remember, mineral spirits are ideal for dissolving and removing old grease from the gears. The toothbrush will help scrub the gear teeth, and the clean rag will be used to wipe down the gears after cleaning. The vacuum or spray gun will be used to blow off dust and debris from the gear train and other parts of the planer.

Additionally, you may need Simple Green cleaner and paper towels to clean the feed rollers. For lubrication post-cleaning, motorcycle chain oil is highly recommended due to its ability to handle high speeds and sawdust contamination.

Safety Precautions Before Starting

Safety is paramount when working with machinery. Before you begin the cleaning process, ensure your thickness planer is unplugged to prevent any accidental starts. Always wear gloves when handling mineral spirits and other cleaning agents to protect your skin. Furthermore, ensure you’re working in a well-ventilated area to avoid inhaling fumes from the cleaning agents. Don’t forget to wear safety glasses to protect your eyes from any debris that might be dislodged during the cleaning process.

Another critical safety precaution is to never force the gears to move while cleaning. If the gears are hard to rotate, plug in the planer, turn it on and off, and then unplug it again to rotate the gears for cleaning. This way, you’ll avoid causing any damage to the gears or injuring yourself.

Taking these precautions is not only necessary for your safety but also to ensure that your thickness planer remains in good working condition. So, now that you understand the importance of cleaning grease from your thickness planer gears and the safety precautions to take, let’s move on to the actual cleaning process in the next part of this guide.

Step-by-Step Guide To Removing Old Grease

The first step in cleaning your thickness planer gears is to remove the old grease. Start by applying mineral spirits to the gears. Mineral spirits are effective in dissolving and loosening the old grease, easing the cleaning process. Use an old toothbrush for scrubbing the gear teeth. The bristles of the toothbrush can reach between the gear teeth, ensuring that all traces of the old grease are removed.

Avoid using harsh cleaners such as lacquer thinner or acetone, as they can damage the components of your thickness planer. Water-soluble cleaners like Goo-Gone should also be avoided. If you need an alternative, you can safely use Dawn dish detergent. However, if you opt for this, be sure to rinse the gears thoroughly and dry them to prevent corrosion.

Cleaning The Gear Area Thoroughly

After removing the old grease, you’ll need to clean the gear area thoroughly to get rid of any residue. A clean rag comes in handy at this point. Wipe down the gears and the surrounding areas to ensure that no grease remnants are left.

For a more thorough cleaning, especially in areas that have accumulated sawdust and debris, a vacuum or a spray gun can be used. These tools are great for blowing off dust and chips from the gear train and other parts of the planer. This step ensures that your planer is not only grease-free but also free from dust and debris that can impact its performance.

Inspecting & Cleaning Feed Rollers

The feed rollers of your thickness planer also need attention. Over time, they can accumulate dirt and debris that can affect the smooth running of your machine. To clean them, use a cleaner like Simple Green applied on a paper towel.

If you find the rollers hard to rotate, you may need to briefly plug in the planer, turn it on and off, and then unplug it again. This action will rotate the rollers, making it easier for you to clean them. However, remember to take necessary safety precautions when performing this step.

By following these steps, you’re not only cleaning the grease from your thickness planer gears but also ensuring that it runs smoothly and efficiently. In the next part of this guide, we’ll discuss how to apply the right lubricant to your cleaned gears and tips for maintaining clean and lubricated gears.

Applying The Right Lubricant

Once you’ve thoroughly cleaned and dried the gears of your thickness planer, it’s time to apply the right lubricant. This step is crucial in ensuring the smooth operation of your machine. Keep in mind that not all lubricants are suitable for your thickness planer gears. Motorcycle chain oil is highly recommended as it can handle high speeds and sawdust contamination, which are common in woodworking.

To apply the lubricant, simply put a small amount on the gears and spread it evenly using a clean rag. Be careful not to apply too much lubricant as it can attract more sawdust and debris, leading to the same problem you’ve just solved. A thin layer of lubricant is enough to protect your gears and ensure their smooth operation.

After applying the lubricant, rotate the gears manually to ensure that it has reached all parts of the gear. This action also helps to distribute the lubricant evenly across the entire gear surface. With your gears now clean and lubricated, your thickness planer should work more efficiently and last longer.

Tips For Maintaining Clean & Lubricated Gears

Now that your thickness planer gears are clean and lubricated, it’s important to maintain this condition for optimal performance. Here are some tips to help you do just that:

Firstly, make it a habit to clean your thickness planer gears regularly. Depending on how often you use your machine, a monthly or bi-monthly cleaning schedule might be appropriate. Regular cleaning helps to prevent the accumulation of grease, sawdust, and debris.

Secondly, always use the right lubricant and apply it sparingly. As mentioned earlier, motorcycle chain oil is ideal for thickness planer gears. Also, remember that less is more when it comes to applying lubricant. Too much lubricant can attract more debris and cause the gears to malfunction.

Thirdly, always check the condition of your gears before and after use. If you notice any abnormalities, such as unusual sounds or difficulty in rotating, it might be time to clean and lubricate the gears.

Finally, always follow the manufacturer’s instructions on maintenance. They are often the best source of information on how to care for your specific model of thickness planer.

By following these tips, you can ensure that your thickness planer gears remain clean and lubricated, leading to a smoother operation and increased lifespan for your machine. Remember, a little maintenance goes a long way in preserving the efficiency and longevity of your woodworking tools.

So, there you have it. A simple guide to cleaning, lubricating, and maintaining your thickness planer gears. With these steps, you can ensure the optimal performance and longevity of your machine, making your woodworking projects more enjoyable and efficient.