A thickness planer is an indispensable tool in any woodworker’s kit. It’s a device we use to trim boards to a consistent thickness throughout their length and flat on both surfaces. But, like any tool, it’s essential to understand how to use it correctly to get the best results.

A key aspect to consider when using a thickness planer is the direction of the wood grain. Wood grain refers to the alignment, texture, and look of the wood fibers. It’s the pattern formed by the wood cells, and it significantly impacts how the wood reacts when we try to cut or shape it.

Wood Grain: With The Grain vs. Against The Grain

Put, ‘with the grain’ means cutting or planing in the same direction that the wood fibers are aligned. In contrast, ‘against the grain’ means cutting or planing in the opposite direction.

Most woodworkers will tell you that it’s best to work ‘with the grain.’ This is because the wood fibers lay down and slice off cleanly when you cut in the direction they’re aligned. On the other hand, if you cut ‘against the grain,’ the fibers can lift or tear, leading to a rough surface.

Why Planing Against The Grain is Not Recommended?

Planing against the grain is not advisable. Here’s why:

Firstly, when you plane against the grain, there’s a high risk of damaging the wood. The planer blades are designed to cut with the grain. So, when they’re used against the grain, it can cause the wood fibers to lift and break. This leads to an uneven surface and potential tear-outs or blowouts around the edges.

Secondly, the quality of the finish you get when you plane against the grain is usually inferior. The surface tends to be rough and damaged, requiring a lot of additional work to correct. You might need to spend a significant amount of time sanding the wood to smooth out the surface. Even then, you might not achieve the smooth finish you desire.

In the end, planing against the grain can cause more harm than good. It can lead to a damaged piece of wood, a rough finish, and a lot of wasted time trying to correct the mistakes. So, while it might seem like a faster way to get the job done, it’s usually not worth the risk.

Potential Risks of Using a Thickness Planer Against the Grain

One of the primary risks is damage to the wood. When you plane against the grain, you’re going against the natural alignment of the wood fibers. The result is often an uneven surface with tear-outs, blowouts around the edges, and potential damage to the wood.

Another risk is the damage to the planer itself. The blades of a thickness planer are designed to work with the grain, not against it. Using it against the grain can dull the blades more quickly, leading to more frequent replacements and increased expenses.

Common Issues: Tear-Out & Surface Damage

When planing against the grain, ‘tear-out’ is a common issue. Tear-out happens when the planer blades lift and break the wood fibers instead of cutting them cleanly. This can leave the wood surface rough and uneven, not the smooth finish we usually aim for in woodworking.

Surface damage is another common problem when planing against the grain. As the planer blades lift and break the wood fibers, they can cause damage to the wood surface. This damage is often visible as marks or scratches on the surface, ruining the aesthetic appeal of the wood.

Safety Concerns When Planing Against The Grain

Safety is a major concern when using a thickness planer against the grain. As the planer blades lift and break the wood fibers, small pieces of wood can fly out at high speed. These wood chips can cause injury if they hit you. Moreover, the force exerted by the planer on the wood can cause the wood to crack or splinter, posing additional safety risks.

In addition to personal safety concerns, planing against the grain can also lead to unnecessary wear and tear on your planer. As mentioned earlier, planer blades are designed to cut with the grain. Using them against the grain can dull the blades more quickly, leading to more frequent replacements and increased expenses. This can also increase the risk of the planer malfunctioning, which could potentially cause harm.

While it’s technically possible to use a thickness planer against the grain, it’s not a recommended practice. The risks of doing so – including damage to the wood and the planer, safety concerns, and the additional time and effort required to fix the resulting issues – far outweigh any potential benefits. So, stick to the rule of thumb in woodworking: always plane ‘with the grain.’ It’s the safer, more efficient, and more effective way to work with wood.

Alternatives To Planing Against The Grain

When it comes to woodworking, it’s crucial to remember that every tool has a purpose. While a thickness planer is an excellent tool to have, it’s not always the best choice for every job. If you find yourself dealing with wood that has grain running in different directions, there are alternatives to planing against the grain.

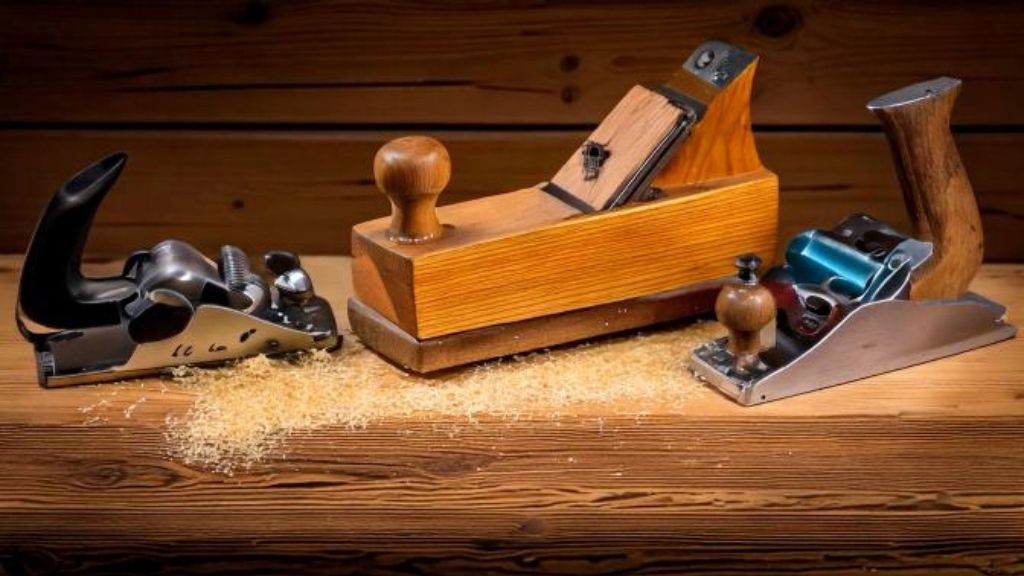

One such alternative is using a hand jointer. A hand jointer is a tool designed to flatten and square up the edges of a piece of wood. Because you have more control over the tool, you’re less likely to cause tear-outs or blowouts.

Another alternative is a drum sander. This tool uses a rotating drum covered in abrasive material to sand the wood. Drum sanders are particularly useful for dealing with challenging grain orientations as they are less aggressive than planers, reducing the risk of damaging the wood.

A handheld belt sander is also an option. This tool is excellent for leveling and smoothing surfaces. It’s especially useful when you need to work on a large area or if the grain direction changes frequently.

Tips For Achieving A Smooth Finish

Achieving a smooth finish on wood without planing against the grain is entirely possible. Here are a few tips to help you get that desired smooth finish:

- Use Sharp Blades: Whether you’re using a planer, a hand jointer, or a hand plane, make sure the blades are sharp. Dull blades can cause tear-outs and leave a rough surface.

- Go Slow: Don’t rush the planing process. Taking your time allows for a more precise cut and a smoother surface.

- Use Fine Grit Sandpaper: After planing, use fine grit sandpaper to smooth out any minor imperfections. This can give your wood that final touch of smoothness.

Expert Opinions

Most experts agree that planing against the grain should be avoided. According to professional woodworkers, the risks of damaging the wood or the planer, coupled with the safety concerns, make it an unfavorable practice. Instead, they recommend using other tools or techniques when dealing with difficult grain directions.

For example, many experts suggest using a scraper or a hand plane for tricky grain orientations. These tools provide more control and are less likely to cause tear-outs.

Furthermore, experts often emphasize the importance of understanding wood grain. By knowing how the grain runs and how it affects the planing process, you can choose the most suitable method for each piece of wood.

In woodworking, the best practice is to always work with the grain whenever possible. It’s safer, more efficient, and yields better results.

Conclusion

In the end, understanding how to work with wood grain, knowing when to use a thickness planer, and being aware of alternative methods can significantly impact your woodworking results. Even though planing against the grain might seem like a shortcut, it’s rarely worth the potential risks and challenges.

By making informed decisions and using the right techniques, you can achieve a smooth and beautiful finish on your woodwork projects. After all, woodworking is not just about the final product, but also about the process and the satisfaction derived from creating something by hand.